Empire Coating Solutions: Your Premier Partner for Kretus Products

Empire Coating Solutions is a leading partner for Kretus products. Discover high-performance epoxy, urethane cement, and decorative flooring systems for your next project.

Turn Your Passion Into Profit: Why 2026 is the Year to Master Epoxy

Why Professional Concrete Coatings are the Best Investment for 2026

Discover why Empire Coating Solutions is the leading choice for epoxy flooring in 2026. From metallic finishes to industrial-strength coatings, we provide durable, high-end floor transformations.

The Foundation of Perfection: Why Self-Leveling is Non-Negotiable for Your Next Floor

Don't let uneven concrete ruin your investment. Discover the importance of self-leveling underlayments and how Empire Coatings creates the perfect foundation for high-performance epoxy finishes.

Empire Coatings: Why Were a Top Choice for Epoxy in California

Discover why Empire Coatings is a leading provider of high-performance epoxy, metallic, and concrete coating systems across California. Get superior quality and support.

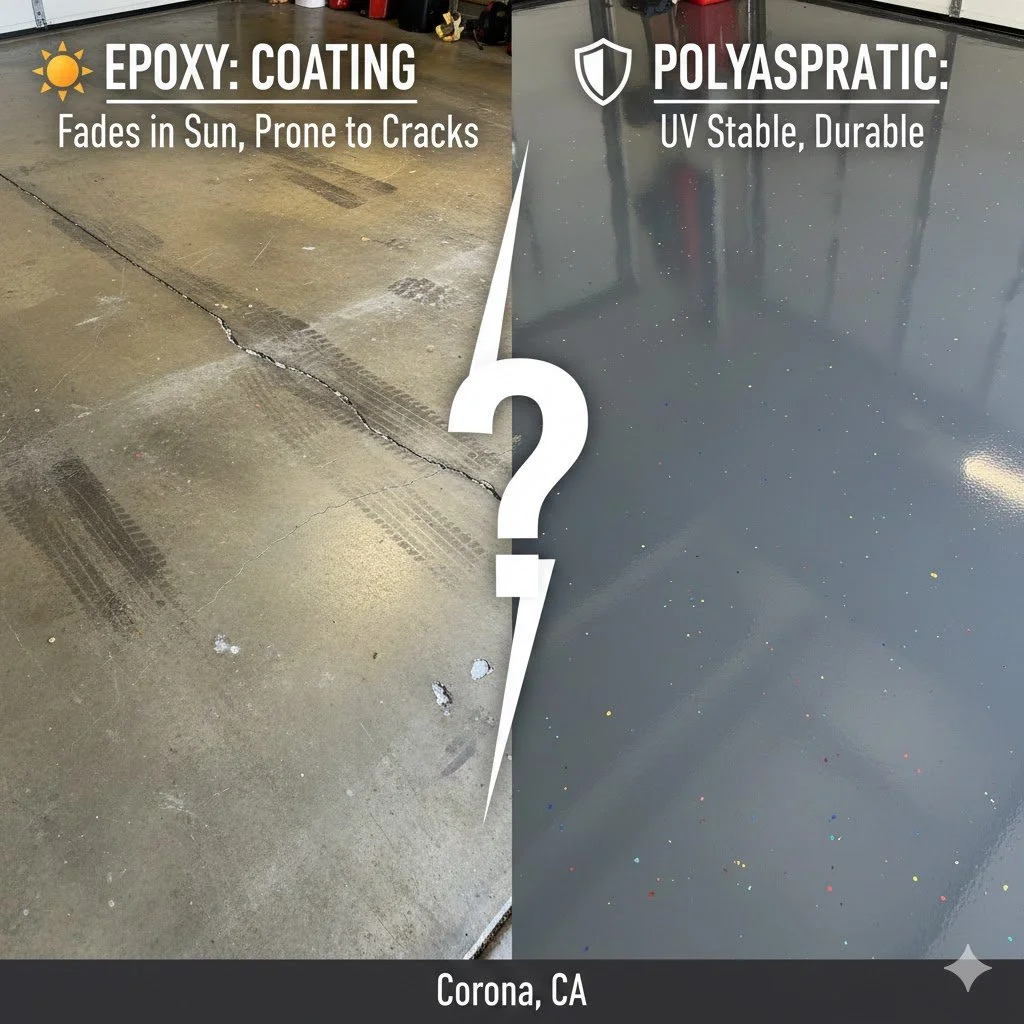

Epoxy vs. Polyaspartic: Which Coating is Right for Your Garage/Patio Floor in Corona, CA?

Corona, CA homeowners: Should you choose epoxy or polyaspartic for your garage or patio? See the pros, cons, and why polyaspartic is best for the hot SoCal sun.

Elevate Your Space: The Magic of Cohills Pro Series Metal Essence Metallics

Discover the magic of Cohills Pro Series Metal Essence Metallics. Learn how these pigments create stunning, one-of-a-kind 3D metallic epoxy floors. Shop at Empire Coating Solutions.

Design Beyond Paint: Unleashing Creativity with Decorative Epoxy Floors

Discover how decorative epoxy floors transform any space with stunning, customizable, and durable designs. Go beyond paint for a truly creative finish!

Beyond the Kit: What "Professional-Grade" Epoxy Application Really Means

Understand the true value of professional epoxy application. Learn why a contractor's prep work, materials, and expertise ensure a superior, lasting finish over any DIY kit.

Why is My Epoxy Floor Peeling? Common Causes & Permanent Solutions

Stop the peeling! Learn the common causes of epoxy floor peeling (prep, moisture, materials) and discover the professional-grade, permanent solutions to restore your floor.

The Superior Mechanical Bond: Why Grinding Concrete is Essential for Long-Lasting Epoxy

Forget acid etching! Learn why professional concrete grinding is the ONLY way to create a superior mechanical bond for an epoxy floor that won't peel, bubble, or fail over time.

Concrete Grinder Rentals & Supplies: Get Pro Surface Prep Equipment in Southern California

Need a concrete grinder for your epoxy prep? Empire Coating Solutions offers premium grinder rentals, diamond tooling, and full surface prep supplies for contractors in Corona, CA and Southern California.

Concrete Stains: The Ultimate Guide to Types, Benefits, & Application

Considering concrete stains? We compare acid vs water-based concrete stain, explain why it won't peel like paint, and provide a guide to stain concrete floors for a durable, high-end look.

Find Premium Epoxy Supplies Near Me: Everything Your Project Needs at Empire Coatings

We understand the unique demands of the California market, from high-humidity coastal areas to dry desert heat. This is why we focus exclusively on the high-performance products that allow you to create stunning, durable surfaces.

Drive Smarter, Not Harder: How Flake Floors Extend the Life of Your Tires

The garage is more than just a place to park your car—it’s an extension of your home and a protective zone for your most valuable assets. You invested in quality tires for performance and safety, so why let your bare concrete floor silently chew away at their lifespan?

A Contractor's Guide to Surface Renewal: Applying Epoxy over Old Concrete

Why Warehouses are Choosing Epoxy and Polished Concrete Floors

The Ultimate Guide to Concrete Sealing with Epoxy Resin

What You Need to Know About Yellowing Epoxy Resin

The Best Concrete Grinder for You: A Contractor's Guide

A good-quality, reliable floor grinder is the essential component of any concrete surface preparation. With so many options available, it can be difficult to choose the one that will suit your needs. At Empire Coating Solutions, we believe the right choice depends on your specific projects. This guide will help you navigate the key considerations when selecting a concrete grinder.